Slewing Ring Bearings

Slewing ring bearings can accommodate axial, radial and moment loads acting either singly or in combination and in any direction. So they are widely applied on engineering machinery (Mobile crane, Tower type crane, Excavator, Loader), Metallurgical Machinery, Transport Machinery, Medical instruments, etc.

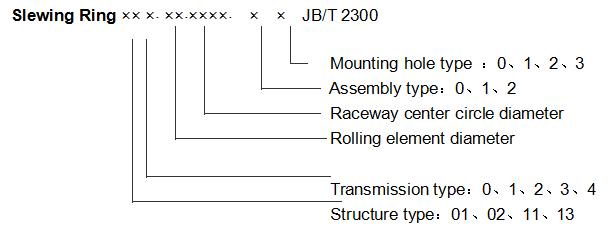

The coding method of bearings

The two coding methods of Slewing Ring Bearings are as following:

1. Adopt the stipulation of JB/T2300 standard, which use raceway center circle diameter, rolling element diameter, structure type, transmission type, assembly type and mounting hole type to show the coding method of bearings.

a. Structure type

a.1 01---Single-row four point contact ball slewing bearings;

a.2 02---Double-row different diameter ball slewing bearings, the combination of rolling element nominal diameter is the above row/the under row: 25/20、30/25、40/30、50/40、60/50 ;

a.3 11---single-row crossed cylindrical roller slewing bearing, the rollers are 1:1 cross banding.

a.4 13- Three-row cylindrical roller slewing bearings, the combination of rolling element nominal diameter is the above row/the under row/radial: 25/20/16、32/25/20、40/32/25、45/32/25、50/40/25。

b. transmission type

b.1 0—without gears

b.2 1—Involutes curve cylindrical gear ext-gear joggle small modulus.

b.3 2—Involutes curve cylindrical gear ext-gear joggle big modulus.

b.4 3—Involutes curve cylindrical gear Int-gear joggle small modulus.

b.5 4—Involutes curve cylindrical gear Int-gear joggle big modulus.

c. assembly type

c.1 0—standard type without ring ridge

c.2 1—standard type with ring ridge

c.3 2—special type

d. mounting hole type

d.1 0—the mounting hole of inner ring and outer ring is through hole;

d.2 1—the mounting hole of inner ring and outer ring is tapped hole;

d.3 2—the mounting hole of inner ring is tapped hole; the mounting hole of outer ring is through hole;

d.4 3—the mounting hole of outer ring is tapped hole; the mounting hole of inner ring is through hole;

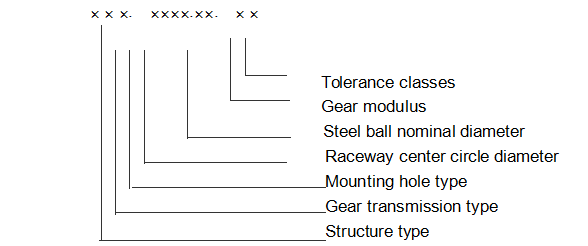

2. Adopt the stipulation of construction industry JJ36.1、JJ36.2、JJ36.3 to show the coding method of bearings.

2.1 Which use raceway center circle diameter, rolling element diameter, tolerance

classes, gear modulus, mounting hole type and gear transmission type to show the coding method of bearings.

a. structure type

a.1 Q— Single-row ball slewing bearings

a.2 J—single-row crossed cylindrical roller slewing bearing

a.3 Z—single-row crossed tapered roller slewing bearing

a.4 S—Three-row cylindrical roller slewing bearings

b. gear transmission type

b.1 W—Ext-gear type

b.2 N—Int-gear type

b.3 U—Without gear type

c. Mounting hole type

c.1 A—the mounting holes of inner ring and outer ring are all through hole;

c.2 B—the mounting holes of inner ring and outer ring are all tapped hole;

c.3 C—the mounting hole of inner ring is tapped hole; the mounting hole of outer ring is through hole;

c.4 D—the mounting hole of outer ring is through hole; the mounting hole of inner ring is tapped hole;

d. Tolerance classes

“G” indicates the precision class, without any note is common class.

e. Gear modulus

“A” indicates the big modulus of this specification, without any note is small

modulus of this specification.

2.2 The old single-row crossed roller slewing bearing which equipped on the existing machine is replaced by single-row ball HSN/HSW slewing bearing, the connect dimension and gear modulus remain unchangeable, which see in the JJ36.1standard appendix A and dimension table of construction industry.

For example: Int-gear type HSN1435.40A Ext-gear type HSW1220.40

2.3 In order to satisfy the series specification which specially supported the introduced goods, it should add “F-;R-”in the front of code, which see in the JJ36.1standard appendix A and dimension table of construction industry.