Tapered Roller Bearings

Tapered roller bearings are mainly suitable to carry combined load---radial load and as well as axial load; While steep angle tapered roller bearings (27°-30°) can carry the combined load dominated by the axial load. The tapered roller bearings are separable bearings, their internal assemblies and outer rings can be mounted separately; the radial clearance and axial clearance can be adjusted when mounting and interference fits are also allowed.

Structures

1.30000 type single-row tapered roller bearings

This type of bearings can accommodate the axial displacement and axial load on one direction on the shaft or housing. An additional axial force will be generated under the action of radial load, so the outer ring and inner ring inside the two bearing slewing should be mounted with their end faces with same name opposite each other. When applied separately, the applied axial force must be larger than the additional axial force.

2.350000 and 370000 types of double-row tapered roller bearings

These types of bearings comprise one double-raceway outer ring (one double-raceway inner ring) and two inner rings (two outer rings). There is a spacer between the two inner rings (two outer rings), To change the thickness of the spacer can adjust the bearing clearance. They can carry radial and double-direction axial load simultaneously.

3. 380000 type four-row tapered roller bearings

This type of bearing adopts two double-raceway inner rings, one double-raceway outer rings and two single raceways. There are spacers between inner rings and outer rings used for adjusting bearing clearance. They can accommodate large radial load. But their limit rotational speed is low so they are mainly applied to heavy-duty machines such as rolling mills.

Cage materials

Tapered roller bearings generally adopt steel sheet cages, when with too large sizes, use welded steel sheet cages or steel pinned solid cages.

Permissible tilt angle

Generally, inclination is not allowed between the shaft and the housing on the tapered roller bearings. If any, it should not exceed 2'.

Tolerance and Clearance

Generally, the tolerance classes of tapered roller bearings is P0, also can produce higher tolerance classes bearings according to the requirement of users. The tolerance value is showing in the section “the tolerance of rolling bearing”.

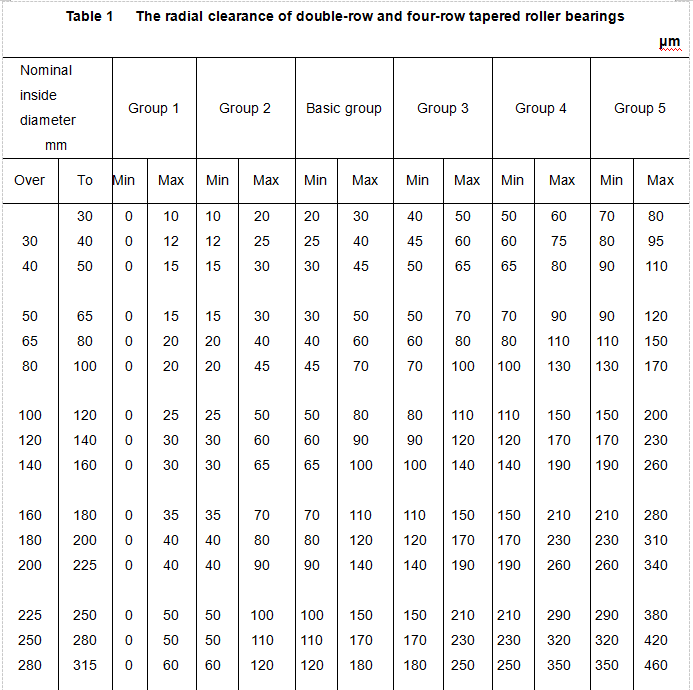

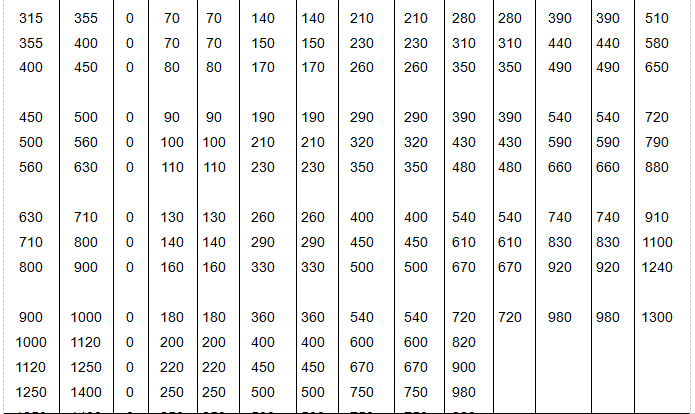

Users can adjust for practical clearance for the single-row tapered roller bearings according to different demands. The radial clearance of double-row and four-row tapered roller bearings is showing in the table 1.

Dynamic equivalent radial load

Single-row tapered roller bearings:

Pr = Fr When Fa/ Fr≤e

Pr=0.4Fr+YFa When Fa/Fr>e

When applying single-row tapered roller bearings in pairs, the additional axial force must be counted when computing the equivalent dynamic load of the bearings. The axial load magnitude is influenced by mounting methods and the applied axial load and the detailed computing method is same as angular contact ball bearings.

The additional axial load on the single-row tapered bearings can be approximately computed with the equation below:

S=Fr/2Y

Double-row tapered roller bearings:

Pr=Fr+Y1Fa When Fa /Fr≤e

Pr=0.67Fr+Y2Fa When Fa/Fr>e

Static equivalent radial load

Single-row tapered roller bearings:

P0r=0.5Fr+Y0Fa

If P0r<Fr, take P0r=Fr

Double-row and four-row tapered roller bearings:

P0r=Fr+Y0Fa

In the equation:

Fr Actual radial load of the bearing

Fa Actual axial load of the bearing

e、Y、Y1、Y2、Y0 see the bearings dimension table.

In order to prevent damaging sliding generated between the rollers and raceway, a minimum radial load must be acted on the bearing. The calculating formula is:

Frmin=0.02C

In the equation: Frmin Minimum radial load

C Basic dynamic radial load rating

Notes: The summary value which convert radial clearance to axial clearance

△a =△r×1.5/e

In the equation: △a radial clearance

△r axial clearance

e Coefficient (see dimension table)